Breakthrough in Sustainable Creatine Production Announced

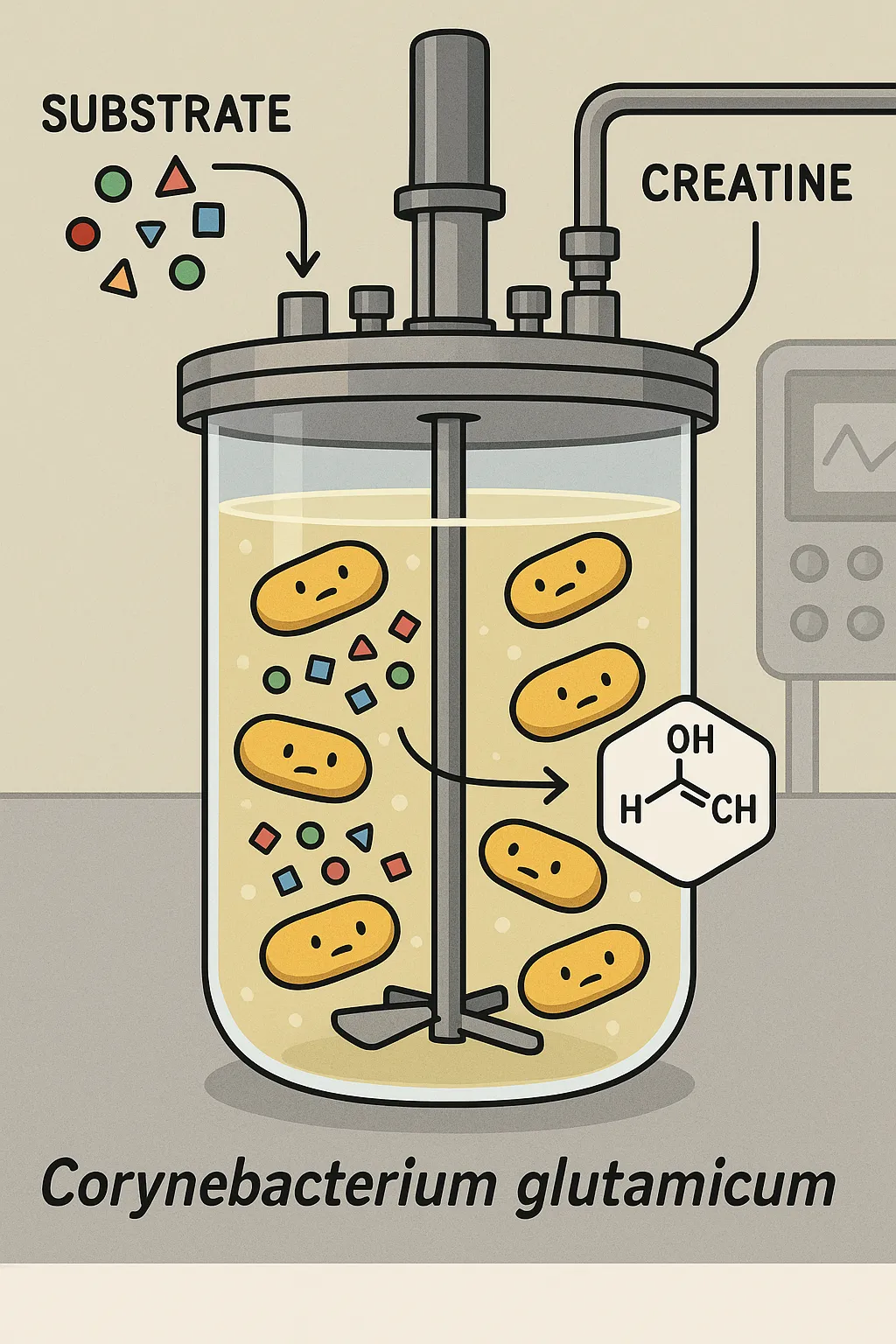

A study out today in ACS Sustainable Chemistry & Engineering reveals a new, cheap way to make creatine. This method uses engineered Corynebacterium glutamicum.

In the paper titled “Economical Production of Creatine in Corynebacterium glutamicum via a Multisubstrate Self-Cycling System,” researchers from the Institute of Industrial Biotechnology report that they have:

- C. glutamicum strains have been engineered to use low-cost feedstocks such as glucose, ammonia, and sarcosine. They convert these materials into high-purity creatine.

- Used a self-cycling fermentation method. This approach regenerates key co-substrates on-site. It helps reduce raw material costs and waste.

- Achieved a creatine titer of 4.2 g/L. The yield was 0.23 g creatine per g of total substrate. This shows a 2- to 3-fold improvement over earlier microbial methods.

Dr. Lena Müller, the lead author, said, “We’ve cut costs in creatine biosynthesis by combining pathway engineering and metabolic recycling.” This opens the door to greener, large-scale supplement production.”

Industry analysts say that global demand for creatine supplements is currently a $640 million market. They expect it to more than triple by 2035. The new bioprocess may cut down the carbon footprint and production costs of creatine monohydrate. This is a big change from the old method, which relies on chemicals from petroleum.

Supplement manufacturers want sustainable options. The authors say pilot-scale validation is the next important step. If it succeeds, this microbial platform might offer affordable and eco-friendly creatine to athletes and the clinical market.

Categories

Autos and vehicles Beauty and fashion Business and finance Climate Entertainment Food and drink Games Health Hobbies and leisure Jobs and education Law and government Other Politics Science Shopping Sports Technology Travel and transportationRecent Posts

Tags

Archives

08/19/2025 (3) 08/20/2025 (40) 08/21/2025 (27) 08/22/2025 (22) 08/23/2025 (4) 08/24/2025 (21) 08/25/2025 (30) 08/26/2025 (24) 08/27/2025 (29) 08/28/2025 (16) 08/29/2025 (9) 08/30/2025 (13) 08/31/2025 (17) 09/01/2025 (167) 09/02/2025 (124) 09/03/2025 (149) 09/04/2025 (112) 09/05/2025 (72) 09/06/2025 (169) 09/07/2025 (162) 09/08/2025 (150) 09/09/2025 (176) 09/10/2025 (194) 09/11/2025 (194) 09/12/2025 (186) 09/13/2025 (207) 09/14/2025 (159) 09/15/2025 (175) 09/16/2025 (198) 09/17/2025 (196) 09/18/2025 (196) 09/19/2025 (207) 09/20/2025 (129) 09/21/2025 (4)